Promotion of CSR

Quality Assurance

Basic Approach

Quality Policy

Yokowo is committed to achieving quality that delivers customer satisfaction. To do that, we respond diligently to the development and improvement requirements of the world-class companies that are leading the global technological revolution, establish optimal quality standards for all products we produce, and make effectively use of our proprietary technology.

Quality Control Activities

Since its founding, Yokowo has been carrying out exhaustive quality assurance activities through quality management with the view to becoming a supplier of top-quality products. Yokowo was certified with the ISO 9001 in 1995 and, subsequently, with the QS-9000 in 1999. Yokowo shifted from its certification to the IATF16949 certification in 2018.

Additionally, Yokowo's principal production bases in Japan and overseas have obtained the ISO certification and the Yokowo Group as a whole implements quality assurance activities in an effort to boost customer satisfaction.

DOMESTIC

| ISO Certifications | Certificate Registration No. | Certification Body | |

|---|---|---|---|

| YOKOWO CO., LTD.(HEADQUARTERS, TOMIOKA PLANT, YOKOWO MEMS DEVELOPMENT CENTER, OSAKA BRANCH, CHUBU BRANCH, UTSUNOMIYA BRANCH) | ISO9001:2015 | JMI-0150 | JQA |

| YOKOWO COMMUNICATION COMPONENTS & SYSTEM CO., LTD. | |||

| YOKOWO PRECISION CO., LTD. | |||

| YOKOWO CO., LTD. (Medical Devices Business) |

ISO13485:2016 | Q5 078509 0005 Rev.03 | TUV SUD |

OVERSEAS

| ISO Certifications | Certificate Registration No. | Certification Body | |

|---|---|---|---|

| DONGGUAN YOKOWO CAR COMPONENTS CO., LTD. | IATF16949:2016 | 0491728/2023A585 | CASC |

| ISO9001:2015 | 01223Q30968R5M | CEPREI | |

| YOKOWO ELECTRONICS (M) SDN. BHD. | QMS 00435 | SIRIM QAS International | |

| YOKOWO MANUFACTURING OF AMERICA LLC | 951 04 2780 | TUV SUD | |

| YOKOWO VIETNAM CO., LTD. | VN010536 | Bureau Veritas Certification |

*Reference: ISO Certification Acquisitions

Quality Assurance System

The Yokowo Group is promoting quality assurance in collaboration with its group companies under the following system.

Data

Concerning soldering as a special process, we have set up a Soldering Training Room at Tomioka Plant and grant internal certification, aiming to explore and pass down knowledge and skills. The internal certification is granted by lecturers certified under IPC, which are global standards. We also promote acquisition of IPC qualifications at locations overseas.

| Standards | Standard name | Number of Employees | |||

|---|---|---|---|---|---|

| Japan | China | Vietnam | Taiwan | ||

| IPC-A-610 | Acceptability of Electronic Assemblies | 1 | 2 | 0 | 0 |

| IPC J-STD-001 | Requirements on electric and electronic assemblies that are soldered | 1 | 4 | 0 | 0 |

| IPC-7711/21 | Rework, Modification and Repair of Electronic Assemblies | 2 | 0 | 0 | 4 |

Major Initiatives

Exhibition Room for Past Troubles*

Our Quality Assurance H.Q. has set a slogan, "Create a quality culture that will not let past troubles be forgotten," under which it drives activities to raise the awareness of all employees.

It exhibits actual goods involved in past quality problems and explains them using videos and panels. The exhibits are revised twice a year. Each time they are revised, all employees are given time to see them.

* The term "past troubles" refers to a record of quality problems that occurred in the past.

QC Circle Activities

We are committed to QC circle activities. The improvement efforts are continued at each workplace and have proved effective. Moreover, we hold a biannual company-wide session for presentations by teams that have won block competitions, with the participation of senior management.

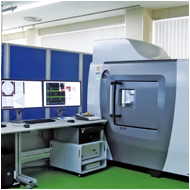

Reliability Test

Yokowo has introduced a large number of environmental composite testers and other testing equipment to its Reliability Laboratory and is constantly working to supply premium-quality products that are compatible with the latest technological innovations.

- Reliability Test Equipment

Liquid Type Thermal

Liquid Type Thermal

Shock Chamber Micro Vickers

Micro Vickers

Hardness Tester Rattle Noise Measurement

Rattle Noise Measurement

Evaluation Device Reliability Test Equipment

Reliability Test Equipment

- Analysis Equipment

Field Emission SEM

Field Emission SEM Focused Ion Beam

Focused Ion Beam X-ray CT Solver

X-ray CT Solver Contact Probe's

Contact Probe's

CT Image